Game-Changing PerfPro™ Perf & Squeeze Method Saves Over 24 Hours of Rig Time & $1M in Deepwater Permanent Well Abandonment

Overview

During a recent deepwater permanent abandonment operation in the Gulf of America (GOA), Oilfield Service Professionals (OSP), in collaboration with Lee Energy Services (LES), successfully executed an innovative low-risk, BSEE-approved solution. This approach was critical in addressing mechanical BOP limitations that prevented conventional cut-and-pull operations for the 14.15” casing string.

Challenges

The well presented significant mechanical and operational risks, including:

BOP constraints that restricted access for traditional casing removal.

High-risk LMRP interventions, which could introduce debris into the well, leading to costly extended work scopes.

Unknown casing centralization, increasing the likelihood of unintentional perforation across multiple casing strings when using explosive perforating guns.

Solution: PerfPro™ Perf & Squeeze Method

To overcome these challenges, OSP and LES implemented a single-trip Perf & Squeeze method, providing a safer, faster, and cost-effective alternative to conventional approaches. This includes the NEXUS™ High-Pressure/High-Tensile Packer, Gator™ Perforator, CatchPro™ Dart/Ball Catcher, & BarrierPro™ Hydra-Set™ Bridge Plug with Scraper System.

Key Advantages:

- Eliminated high-risk LMRP intervention, preventing potential well debris issues and avoiding an extended rig scope of several days to weeks.

Ensured access to the 14" x 22” annulus above the 16” TOL, enabling placement and verification of two critical zonal isolation barriers.

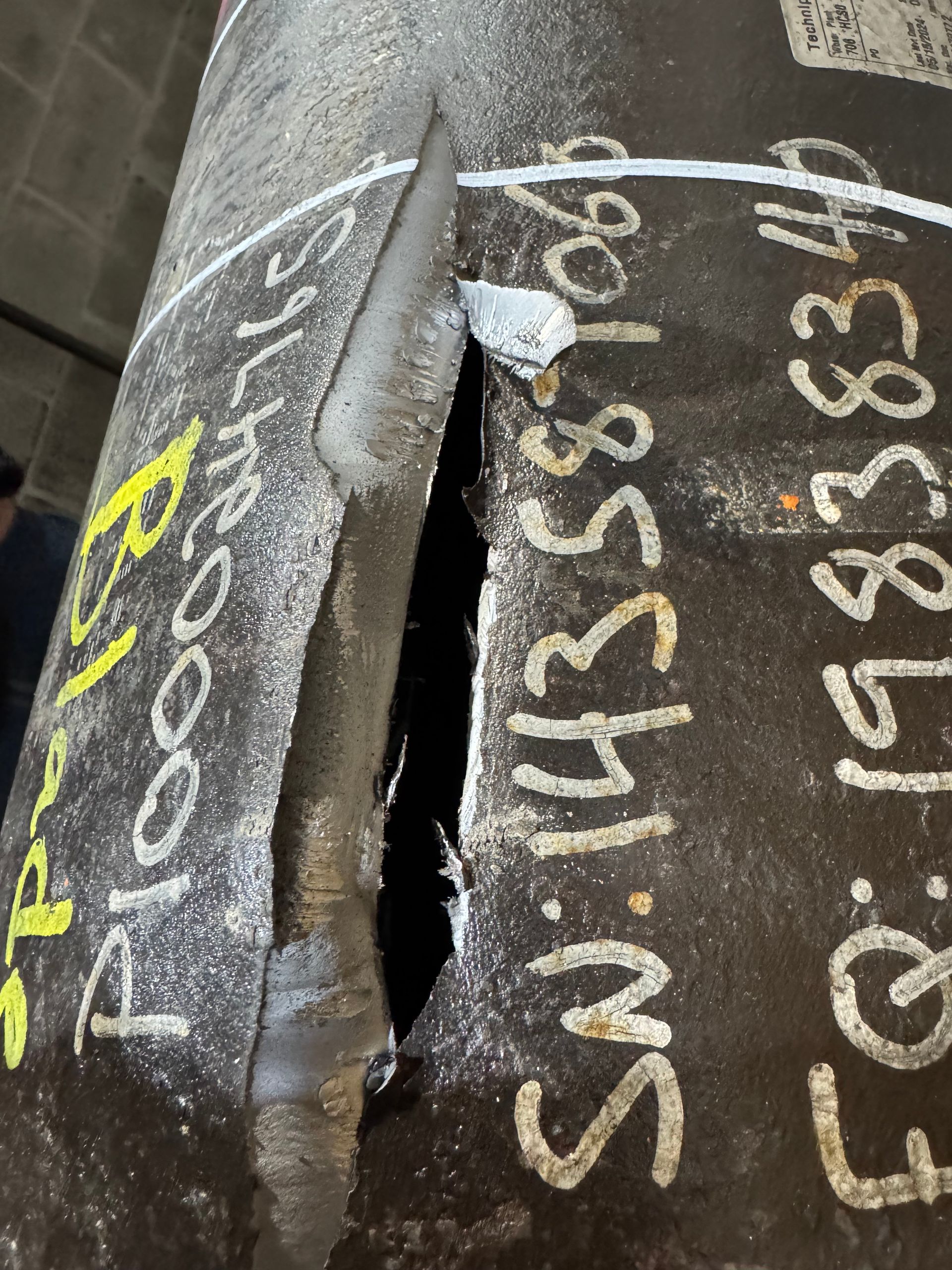

Executed rapid planning, testing, and deployment, including a pre-job perforation test on 14.15” casing to confirm operational feasibility.

Reduced reliance on explosive perforating guns, mitigating risks associated with multi-string perforation due to unknown casing centralization.

Results & Impact

This innovative approach has redefined the operator’s P&A strategy, leading to:

- Over 24 hours of rig time saved

- More than $1M in operational cost savings

- A validated BSEE-approved methodology that eliminates traditional cut-and-pull operations.

Moving forward, this methodology allows Perf & Squeeze to serve as the primary P&A method for wells of this design in deepwater GOA operations, representing a major shift in deepwater abandonment operations.